This story was written by Dr. Dale R. Carlson, Advanced Technology and Preliminary Design, GE Aviation for AirlineReporter.com.

I’ve been passionate about aviation for as long as I can remember. So, as a leader of technology development for GE Aviation, I consider myself one of the luckiest guys in the world.

My team and I get to experiment with and investigate technology that will be used in the aviation industry decades from now ’¦ exciting things like electric and hybrid propulsion, self-healing materials and blended wing bodies. What most people don’t realize is the amount of time it takes to develop these complex, game-changing technologies.

It’s not like the consumer electronics world of computers and smartphones where new models become obsolete within six months. In our aviation world, developing new technology takes time, sometimes 30 years (or even more!).

Why does it take so long? Because we need to prove that every new technology does not negatively impact flight safety. You wouldn’t want it any other way!

Let’s take the introduction of composite materials ’“ including carbon fiber ’“ into a commercial turbofan engine, for example. We began working on composites development in the 1970’s through a NASA program, tested it in the 1980’s for the unducted fan engine, and finally commercially introduced it a decade later on the GE90 engine powering the Boeing 777 aircraft. This was a 25+ year process. Check out the video below for more information about the research and development of our composites.

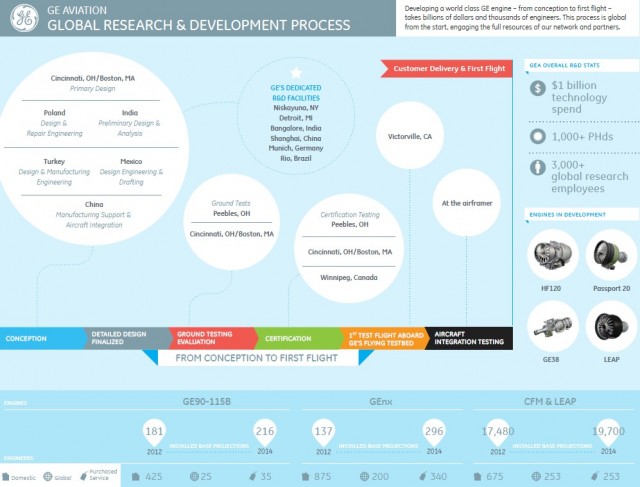

As you can imagine, this exciting technology takes a lot of time, money and people to develop. GE spends more than $1 billion in R&D year over year. To get a better picture of how such an extensive R&D team works, see our new infographic of our global network of scientists and experts working to bring engines from concept to ’œfirst flight.’

Luckily, we also have tools today that enable us to build products more efficiently. Sometimes we can even use digital engine models with computer simulation as a means for certification testing (where appropriate). We also conduct module rig tests and individual component tests prior to testing the engine as a system. Watch the video below to see our flight test airplane in action.

In fact, we used these digital testing tools to certify the GEnx, our newest and most fuel-efficient jet engine yet. The GEnx will be on display at this year’s Farnborough Air Show next week, in addition to other military, systems and services offerings. I can’t wait to see what everyone else will be highlighting at the exhibition this year.