INTRODUCTION

Although the Boeing 787 Dreamliner looks similar to previous aircraft, it uses the next generation of technology and materials. Designing, building and then training for such a complex aircraft is no easy task. How does an airline go about preparing to take delivery of a brand new aircraft?

All Nippon Airways (ANA) will be the first airline to take delivery of the 787 and I recently had the opportunity to sit down with Mr. Takeo Kikuchi, ANA’s General Manager of the USA Engineering Office, and with Nao Gunji, ANA’s Communications Coordinator, to learn more about how they are preparing for the Dreamliner.

Today this story will give some background on the Dreamliner and the training that ANA has completed for the 787. Tomorrow, I will post about ANA’s input on developing the 787 and what happens after they take delivery.

I felt honored to have the opportunity to speak with Mr. Kikuchi. He started working in the airline business in 1980 as a mechanic and did heavy maintenance on classic Boeing 747s in Japan. Subsequently he was responsible for overseeing hydraulic systems on, allowing him to expand his engineering experience. He then worked in public relations for about three years before moving to Seattle in 2007 to lead the local ANA engineering office at Boeing.

Mr. Kikuchi’s main responsibility is to communicate to Boeing the needs of his airline and ensure ANA receives the best quality plane possible. ’œANA’s drive is to purchase a reliable, convenient and usable airplane,’ he explained.

787 AIRCRAFT MATERIALS

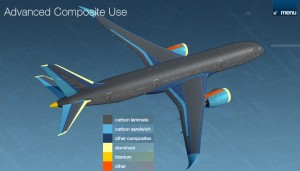

The type of materials used is one way the 787 is unique from other aircraft (what makes the 787 different). Currently most aircraft are built using large aluminum panels and are riveted to a metal frame. In contrast, the 787 is constructed using large sections of mostly carbon composite materials that do not need to be riveted. Although the new material makes for a stronger and lighter aircraft, it can provide some challenges.

One of those challenges is how to repair the aircraft. To repair an aluminum aircraft, ANA puts a temporary patch on the affected area and then flies the damaged plane to their maintenance facility in Japan for a permanent repair. With carbon fiber, it is not as easy and will be more difficult to complete a temporary repair before flying to a repair facility. ANA is currently working with Boeing on perfecting the best way to make short-term repairs to the Dreamliner.

One advantage of a carbon fiber repair is the long term benefits. With an aluminum repair, an airplane will have additional squares of aluminum riveted onto the fuselage, causing additional weight and lowering aerodynamics ’“ raising fuel costs. After 787 composite repairs, the change of the aircraft weight and aerodynamics will be minimal, saving money over the lifetime of the airframe.

Japanese reporters getting a look at one of the two 787 full flight simulators in action at the Boeing/ANA training campus in Tokyo on March 7. Photo by Boeing.

ANA TRAINING

Although there are many forms of training, nothing beats hands-on experience. Mechanics have started with computerized training, but at some point will be flown from Japan to Paine Field in Everett, WA where the Dreamliner is built. To date, there have been over 100 ANA mechanics, who visit in groups of 10-12, who have been flown to Seattle to train on the Boeing 787 Dreamliner.

Even though there have been ANA pilots who have flown the Dreamliner, not all the pilots will have that chance before the airline takes delivery. The Japanese Civil Aviation Bureau (JCAB) approved Dreamliner simulators at the ANA/Boeing training campus in December 2010. ANA will start 787 pilot training as early as this month.

ANA has invested a lot of time, money and their future into the Boeing 787 Dreamliner and Boeing knows how important their relationship with ANA is. “I can’t say enough about Boeing’s special relationship on 787 crew training with ANA over the past four-plus years, ’ Sherry Carbary Vice President, Flight Services, Boeing Commercial Airplanes said. ’œTheir attention to detail was outstanding and made us better for it.’

After speaking with Mr. Kikuchi, I had a quick tour of the Boeing factory and the 787 production line (sorry, no photos). Now, I am no stranger to the factory, but this was much different tour being that I was guided by an airline representative and hearing their perspective.

While getting a tour of one of their 787 Dreamliners in production, we saw a group of ANA mechanics getting a quick look at the aircraft. Mr. Kikuchi told us that the mechanics would be given a scenario concerning a problem and they would learn how to solve it. It is one thing to talk about the 787 in a conference room versus being out with on the aircraft and seeing the mechanics in action.

Talking to ANA About the 787 Dreamliner:

PART 1 | PART 2 | BOTH

Wondering what ever happened to B787 with ANA logo caught fire.