Not an angle that one sees often of a Boeing 747-400

“We actually don’t do that work here. For that kind of thing, we have to ship it out to Lufthansa Technik in Germany.” If you talk to a great number of airline maintenance employees around the world, you’ll probably hear that line a few times. Many airlines are capable of doing their own aircraft maintenance, but few locations in the world take MRO (Maintenance, Repair, and Overhaul) to the level Lufthansa Technik does.

Airlines around the world send their aircraft to Technik for jobs ranging from a mandatory C check to a nose-to-tail cabin refurbishment. Recently, I was invited to tour Technik’s facilities in Hamburg, Germany, which is just one of their multiple full-service locations around the world.

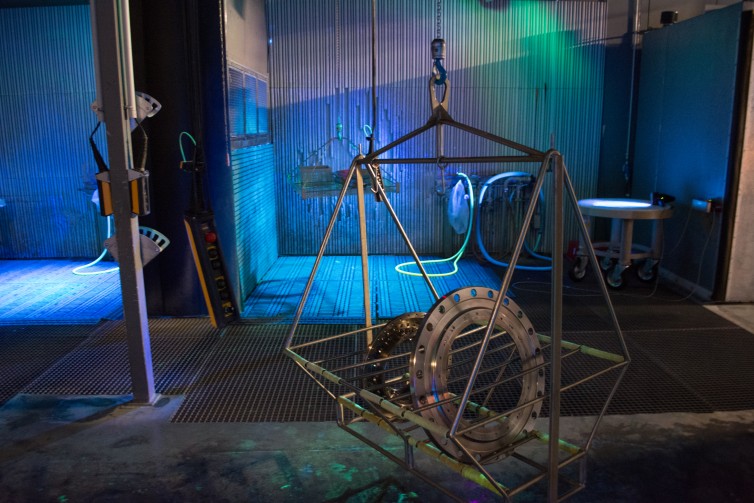

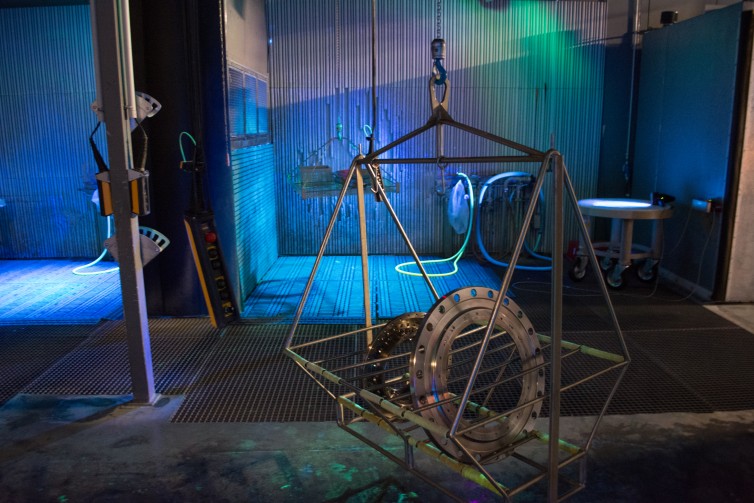

One of the black light inspection areas in Lufthansa Technik Engine Shop – Photo: Jason Rabinowitz

Our first stop on the Engine Services center. Engines are, by far, some of the most expensive parts on any aircraft. Most airlines perform only minor maintenance on their engines, but in the Engine Services center, several engines were completely torn down for a total rebuild.

Air New Zealand’s “Pleased to Seat You” truck on display in Terry Fox Square in Vancouver

Air New Zealand is in the midst of refurbishing its Boeing 777-200ER fleet, and is showcasing the planes’ new Premium Economy and Economy Skycouch seats during a North American ’œPleased to Seat You’ tour.

The seats are on display in a 26 foot, 5 ton, glass-walled truck that will cover more than 7,000 miles, giving the public a chance to see and sit in the -200’s new seats. The airline introduced the innovative Skycouch in its Boeing 777-300s ’“ the footrest in a row of three seats can be positioned at the same height as the seat cushions, giving a flexible space for passengers.

With the update of the -200s, all of the long-haul aircraft in Air New Zealand’s fleet will include the Skycouch, along with the new Premium Economy seats also found in its Boeing 787-9s.

British Airways flight 2276 at Vegas – Photo: McCarran Airport

Today, we at AirlineReporter share two different opinions on passenger evacuations of an airliner during an emergency. In recent incidents, we have seen passengers taking their bags and people reacting. This story shares the opinion that it is not that big of a deal to take your bag and is written by an anonymous writer (that has been verified), who is a frequent flier, no stranger to the airline business, and is a writer. Be sure to read the opposite opinion and share your thoughts in the comments.

First off, I agree that probably it is best to leave your bag on a crashed/burning airliner. However, the attention that I have seen given to passengers who end up taking their bags with them during an emergency sickens me.

These people just went through a major incident, where many likely felt that they were going to die. Could you imagine going through something like that and then instead of having people asking you if you are okay, they harass you? I wouldn’t want that either. It now seems to be the popular thing to do.

If some of you will take the time to get off your high horse and read this, maybe you won’t be so quick to judge. I argue that people shouldn’t automatically be ostracized for grabbing their bag in the middle of a potentially deadly evacuation.

A flight deck of a Boeing 777.

Today, we at AirlineReporter share two different opinions on passenger evacuations of an airliner during an emergency. In recent incidents, we have seen passengers taking their bags and people reacting. This story shares the opinion that passengers should leave their bags and is written by Captain Owen Zupp, who is a published author, journalist, and experienced commercial pilot with over 17,000 hours of varied flight experience. His story was originally published on ThePilotsBlog.com and shared here, with permission. Be sure to read the opposite opinion and share your thoughts in the comments.

The smoke plume from British Airways Flight 2276 was still reaching skywards as people were posting dramatic images across the internet. Both distant shots and photos from passengers were blinking across the globe as fire crews tended to the stricken Boeing 777. It was a day and an event that aviation professionals dread, and yet it is also the very eventuality that endless hours of training have been directed towards.

Some of the damage on the British Airways 777-200ER at Vegas – Photo: NYCAviation

On the flight deck, a “rejected takeoff” is a maneuver that is part of every recurrent simulator session for pilots. Crews are tested for a range of scenarios, from engine failure and fire, to tire deflation and loss of visibility. Sometimes, the choice to reject the takeoff is obvious; in others, it is more obscure, such as when the failure occurs at low speed with its own directional control issues, or when the problem arises at high speed when the aircraft is beyond its decision speed, or ’˜V-1’, and the takeoff must continue.

Aerial shot of the Airbus facility in Mobile – Photo: Airbus

Story and photos by Chris Sloan; was originally published on AirwaysNews.com on September 14, 2015.

With top level delegations from Airbus and the State of Alabama, Airbus Group today threw open the doors to its first U.S. Final Assembly Line in Mobile, Alabama at the Brookley Aeroplex ’“ The first time a foreign manufacturer has built jets on U.S. soil.

This new production facility, specifically constructed to build Airbus A320 family aircraft destined for delivery to United States and Canadian customers, joins sister factories in Toulouse, Hamburg, and the northeastern Chinese city of Tianjin, where the company recently announced A330s would be constructed beginning in 2018.

Major components of the first two aircraft to be assembled at the Airbus U.S. Manufacturing Facility are shown in the main final assembly hangar – Photo: Airbus

The Mobile final assembly line opens with ambitious goals, befitting the A320 family program. First aircraft assembly began in July with the first U.S.-produced airframe, a JetBlue A321ceo (MSN6512), which is expected to roll out in the first quarter of 2016, with delivery set in the second quarter. The second aircraft, also an A321ceo for American Airlines, is set to be delivered by the third quarter of the next year.

Plans call for an initial production rate of four A320 family ceos per month by the end of 2017, following an initial start of two aircraft per month. With the A321 being ’œthe heart of the U.S. market’, the initial deliveries on the horizon are for the stretched variant. A320neo family deliveries are scheduled to begin in late 2017 / early 2018 with no drop in production rate.