For quite sometime the tension between Boeing and Airbus over the tanker deal and subsidies has created tension. More recently, it seems maybe they are going too far on Twitter, advertisements and comments made.

With Boeing (@Boeing & @BoeingAirplanes) and Airbus (@AirbusInTheUS) recently getting on Twitter, it has become interesting seeing some of the volleys that go back and forth between the companies. Things have been pretty friendly, until news on subsidies surfaced.

I really don’t feel like hashing out all the subsidy stuff, but the bottom line is Boeing accused Airbus of taking illegal subsidies. The World Trade Organization (WTO) found that Airbus took $20billion in illegal subsidies. Boeing has come out pretty saying, “we told you so” (that’s a paraphrase). Then it became Airbus’ turn and now they are stating that the WTO has found Boeing also took illegal subsidies. There is a lot more going on, so if you aren’t up to date, check out Flight Global’s WTO page.

Airbus released the findings on January 31st and during the day they produced nine Tweets talking about the WTO findings and in many, talking directly to Boeing. For example (help with Twitter lingo):

@AirbusInTheUS: “Confused by #Boeing claims that WTO found Airbus got $20B in illegal subsidies? Us too. Here’s the report. http://ow.ly/3NExm No such #’s.”

Okay, I can see one, but nine Tweets? It seemed to be a little much for me. I see Twitter as a way for companies to relate to their customers, not a place to complain directly about a competitor. Sure, if you are Tweeting for yourself, not a company, complain away, but representing a company is something different. You don’t see United Airlines calling out Delta Air Lines on Twitter — it is kept professional as it should.

Boeing also talked about the WTO reports, but were not directly talking to Airbus. Boeing’s approach seems very different to me. Here is an example of Boeing’s tweet on January 31st:

@Boeing: “#Boeing statement on #WTO decision reports http://bit.ly/gRUgXM #Airbus,” and “Video: #Boeing trade expert discusses #WTO www.boeing.com/wto”

I understand that Airbus might have some built up frustration. Not only did Boeing accuse them of getting subsidies and they find Boeing did too, but there is a lot of emotion around the US military tanker deal. The tanker deal has been plagued with delays, decision changes and some pretty messed up situations.

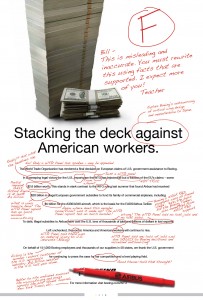

Boeing placed an ad in DC-area newspapers about the subsidies and tweeted it on February 3rd. That Tweet, caused Airbus to respond with two Tweets arguing that the ad was misleading (Tweet1 and 2). But Airbus didn’t stop there. They took Boeing’s ad and made some edits and placed their revised ad in a newsletter targeting the folks on Capital Hill in Washington, DC (see photo with this blog). It seems like Airbus’ edits bring up some interesting points and questions.

In a way, Boeing has an advantage since they have three separate Twitter accounts (their third is on defense). I think this separation was wise. The @BoeingAirplanes has been the more light and “fun” account, connecting with Boeing fans and direct customers. The other two are able to take the brunt of the controversy and have more of a serious tone. Since Airbus only has one feed, it can be difficult to read a serious tweet one second, then the next learning how many ping pong balls can fit into an A380 (by the way, it is 35million). Boeing has also been in the defense business much longer than EADS (the parent company of Airbus). Boeing has been able to learn the ins and outs of defense communications and even has had a lead with social media.

Although Twitter for the two has seemed to calm down, both airline manufactures are still participating in public conflict . EADS North America Chairman Ralph Crosby Jr. recently stated he feels that Boeing cares more about winning the tanker than American troops getting the best product. ’œOur campaign has been based on enabling the understanding of the superior capabilities and value of our system under the rules that are established. And what I see in terms of advertisement and sort of third-party and paid surrogate statements is that, well, whatever (Boeing executives) do, they may or may not win, but they sure want to keep us from winning and, frankly, from my perspective, if that’s anybody’s approach then I think it’s irresponsible to the warfighters.’

Boeing tanker spokesman Bill Barksdale responded by saying, ’œRather than take shots at our European competitor, the Boeing Company continues to focus on being ready to build tankers if we’re honored with a selection and contract award. The selfless men and women of America’s Air Force deserve no less.’

I know there are a lot of complexities and politics involved with this deal, but it seems to me that both companies are spending too much time concerned about insulting the other. That time, effort and money might be used more wisely to work on their own airplane programs.

I think both companies are still in the learning phases of social media. I just hope that whichever company loses the final contract for the tanker can graciously admit defeat and wish the winner the best of luck. I know in the “real” world, that might be too much to ask, but I think in social media, anything is possible.

Image: Seattle PI