A Ryanair 737 taxis for a test flight at Boeing Field – Photo: Andrew W. Sieber | FlickerCC

Ryanair might soon start trans-Atlantic flights, but what does it mean?

At face value, this may seem like an earthshaking headline; after all, Ryanair has been either threatening or strongly implying that they will fly from various European airports to the United States.

But again, the truth is always in the details. Yes, Ryanair will be arriving on U.S. soil, but not tomorrow — not even next year. You see, the exact wording of the approval came in the form as part of their five-year plan.

United’s latest 737-900ER, taxiing at Boeing Field

On Wednesday April 16th, United took delivery of its latest 737, but this one was special.

A 737-900ER was delivered from Boeing Field, marking a special occasion for not only Boeing but also United. The aircraft was the 8,000th 737 to roll out of the Renton factory, and became one of over 550 of the type to be delivered to United since its inception.

WheelTug testing at Prague Airport using a Germania 737-700 in June, 2012. Yes, it’s moving!

Courtesy: WheelTug

You may have read my recent report on the Honeywell/Safran Electric Ground Taxi System, or EGTS. But as we’ve seen countless times with many technologies, there’s rarely just one solution to a challenge. We’ve had the 707 & DC-8 duo, L-1011 & DC-10s, 737 & A320s, PCs & Macs, iThingys & Everything Else… you get the idea. Interesting, though, that the market usually settles down to 2 options. So it should be no surprise that there’s another E-Taxi system, one that takes a different approach to meeting the same objectives of saving fuel, time, and other operational costs.

Gibraltar-based WheelTug decided to figure out a way to power the nose gear in their E-Taxi solution, and not the main gear. Their reasons? Easier and quicker installation; no interference with braking and anti-skid systems; shorter cable runs to the equipment bay under the cockpit; and it’s lighter, on the single nose gear rather than two main gear. But there isn’t much space available on the nose gear and in the wheel well. To make it all work, WheelTug looked to an old idea updated with new technology – the “wheel-hub” electric motor.

No, this A320 isn’t parked. It’s taxiing without the engines running. Check out the video after the break.

Photo: Benoà®t Vallet/Safran

Airlines are doing everything they can to reduce their fuel costs. You may have taken an airline flight recently where the crew taxied to or from the runway on one engine. Or you’ve noticed that the Auxiliary Power Unit (APU) isn’t running when a plane is at the gate. Sometimes, if possible, instead of running the APU the plane can be plugged into “ground power,” getting it’s juice through a big extension cord from the terminal.

Airlines are also playing with new approach procedures that smooth out the descent and path to the runway, allowing crews to bring the power back to near-idle thrust and pretty well glide most of the way to the threshold and saving on fuel. The goal is to try and do anything to save fuel while keeping passengers safe.

Honeywell and Paris-based Safran Groupe have come up with some nifty new technology that could save airlines hundreds of thousands of dollars a year in fuel costs for each aircraft. It’s called the “Electric Green Taxi System” or EGTS, and it was recently demo’d at the Paris Air Show.

Photo of Paine Field taken just a few days ago. Many Boeing planes might have been delivered in 2012, but there are still many parked at KPAE. BTW, looking at this photo you have brand new Boeing planes and Mount Rainier in the background. I love living in Seattle.

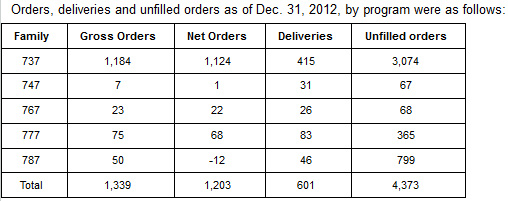

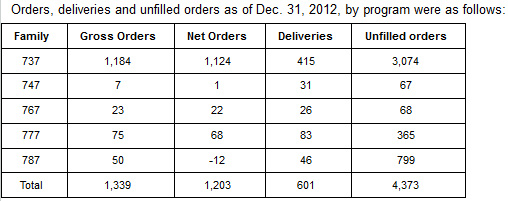

Boeing had a pretty darn good 2012. They received 1,203 net commercial orders and had 601 deliveries. One of the best successes for Boeing was the 737 and the new more efficient MAX model (still not keen on that name).

Of the 1,203 net orders in 2012, 1,124 of those were for the 737 and 914 of those were for the MAX. Not to mention that the 737 celebrated its 10,000th order earlier in 2012.

Boeing orders and deliveries for 2012. Chart from Boeing.

Boeing President & CEO Ray Conner sent a letter to all Boeing Commercial Airplanes employees to recognize their ’˜incredible’ contributions to the company’s success in 2012. I figured it was something worth sharing:

As we kick off a new year, I’d like to recognize your incredible accomplishments in 2012. You’ve demonstrated through your hard work and dedication that you are the best aerospace team in the world.

Thanks to your efforts, we ended the year with 1,203 net orders ’“ the second-largest total in company history. We delivered 601 airplanes ’“ the most since 1999 ’“ and we continued to raise the bar across all programs. We also advanced our services strategy and increased the breadth of our offerings to customers.

On the 737 program, we booked 1,124 net orders ’“ unprecedented for any of our models in a single year ’“ and celebrated the program’s 10,000th order. The Next-Generation 737 set a record for deliveries ’“ 415 in the span of a year. And the 737 MAX logged 914 net orders, pushing us past the 1,000 order mark.

Our strong performance extended to the twin-aisle programs as well. The 787 program closed out the year with 46 deliveries ’“ including 11 Dreamliners in December alone. In all, we have delivered 49 787s to eight customers. The 777 program made a milestone 1,000th delivery, the 747-8 Intercontinental and Freighter continued to receive positive reviews for performance from customers, and the 767 team helped the KC-46 Tanker program meet or surpass its development milestones for the year.

Not only that, in December we delivered 15 airplanes in a 24-hour period from Everett, Renton and Charleston combined ’“ the most in one day since 1998 ’“ highlighting our collective strength as one team. We achieved all this while stepping up production 26 percent over the course of several rate increases throughout the year. This is outstanding work by an amazing team and I know our customers appreciate it.

Looking forward, our customers continue to face an increasingly tough business environment, making it more important than ever that they acquire more-efficient products and services at lower costs. To help meet demand, we’ll continue to focus on raising production rates and continuously improve how we build airplanes. We’ll transition the 787-9 into production and flight test and continue working toward the 787-10X and the 777X, guided by the needs of our customers.

On our development programs, we will be more disciplined as we implement lessons learned from the past. We’ll think early in the process about how we can better support our customers throughout the product lifecycle, while ensuring our own profitability.

With a backlog of 4,373 unfilled orders ’“ the highest in our history ’“ we have huge opportunity ahead of us if we execute on our commitments. We know we have the right products and we’ve proven we know how to increase rates. I know we have the right team to make it possible.

It takes our entire team to be successful ’“ everyone is an important player. That means we need to look out for one another and be relentless about achieving our goal for a safe work environment with zero injuries. It also means having a culture where we treat our teammates with the highest level of integrity and respect. As we all sign Boeing’s Code of Conduct this month, we should think about the kind of culture we want to have ’“ one that makes us proud to work here. Let’s make it happen.

Once again, I’d like to thank you for making last year so successful. I look forward to the year ahead.

Ray

|

This story written by…David Parker Brown, Editor & Founder.

David started AirlineReporter.com in the summer of 2008, but has had a passion for aviation since he was a kid. Born and raised in the Seattle area (where he is currently based) has surely had an influence and he couldn’t imagine living anywhere else in the world.

@AirlineReporter | Flickr | YouTube |