In 1948, United Airlines established a maintenance base at San Francisco International Airport. Seventy years later, the place is still hard at work keeping the airline’s planes safe and in the air. Every year, United brings tens of thousands of its employees to the base for Family Day, and this year the airline invited us to take part.

What a wild, awesome day it was! We got to meet “Chix Fix,” United’s award-winning all-female team of aircraft technicians, go on a tour of the maintenance facility, and celebrate the day with the United family. We even got to sample some food from Boeing’s newest plane: the 777-200BBQ (tail number N1BBQ)! AvGeeks eat your heart out, and read on for plenty of photos from the day’s fun.

Not an angle that one sees often of a Boeing 747-400

“We actually don’t do that work here. For that kind of thing, we have to ship it out to Lufthansa Technik in Germany.” If you talk to a great number of airline maintenance employees around the world, you’ll probably hear that line a few times. Many airlines are capable of doing their own aircraft maintenance, but few locations in the world take MRO (Maintenance, Repair, and Overhaul) to the level Lufthansa Technik does.

Airlines around the world send their aircraft to Technik for jobs ranging from a mandatory C check to a nose-to-tail cabin refurbishment. Recently, I was invited to tour Technik’s facilities in Hamburg, Germany, which is just one of their multiple full-service locations around the world.

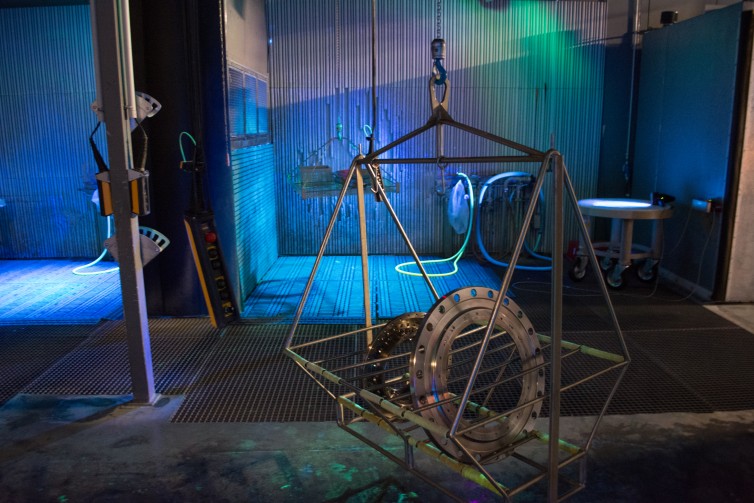

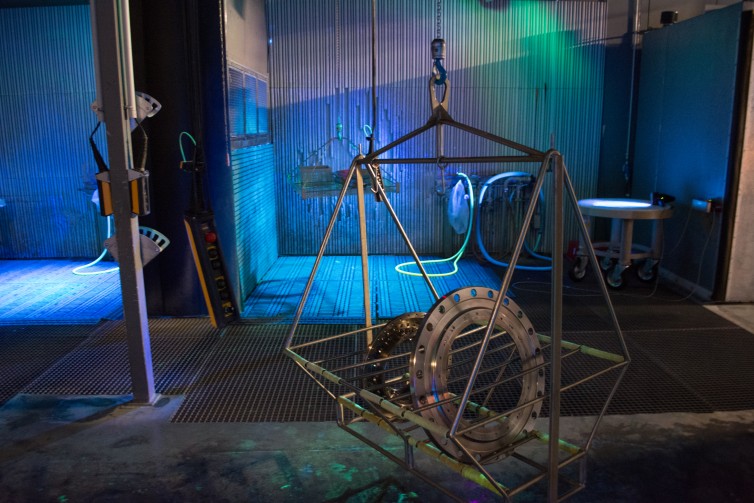

One of the black light inspection areas in Lufthansa Technik Engine Shop – Photo: Jason Rabinowitz

Our first stop on the Engine Services center. Engines are, by far, some of the most expensive parts on any aircraft. Most airlines perform only minor maintenance on their engines, but in the Engine Services center, several engines were completely torn down for a total rebuild.

Forklifting this Beaver to its parking spot for the night

Kenmore Air is the world’s second largest seaplane operator, with their main base of operations located just northeast of Seattle (in Kenmore) and just a few miles away from where I live. I have had a few opportunities to fly their seaplanes, but I have always been wanting to take a closer look at their operations and learn a bit more about how they keep their 18 seaplanes going.

Multiple planes are being worked on inside Kenmore Air’s new hangar

When I heard that they just recently opened up a brand-new maintenance hangar, I figured that this would be a great excuse to get a behind-the-scenes tour. I went in, not fully knowing what to expect, but found out quite a bit about the planes, the facility, and the people that make it all happen.

Sometimes you just have to dive in – Photo: Kris Hull

Working for an airline might seem prestigious to most on the outside: a job filled with adventure and travel, with good perks. However, like with most things, reality if very different. For the past nine years, I have spent my time working as an FAA-certified and licensed Airframe and Powerplant Mechanic, or A&P. A&Ps are the lifeblood of civil aviation in the United States.

In short, we are tasked with ensuring that all aircraft in the US are maintained in an airworthy and safe manor. It is not very glamorous, but it sure is fun! I obtained my A&P license by attending an FAA-approved course for two years at a Washington state community college, and then I entered the aviation workforce with gusto and drive, ready to conquer the world; or so I thought!

FAA A&P mechanics can work on anything, including this PBJ-1J under restoration – Photo: Kris Hull

Throughout my ten years in the aviation industry so far, I have worked for four companies; two for a year or less, and the other two for four years each. I have had the opportunity to work on everything from the diminutive (yet mighty!) Piper J-3 Cub up to the newest member of the 747 family, the 747-8. So sit back and enjoy reading this while I recall some of the adventures (or misadventures!) I have had over the past several years!

Ooops! AA's Boeing 767-300 fell on its nose!

The American Airlines’ 767-300 had just finished undergoing maintenance at Fort Worth when “the nose gear retracted and put the aircraft on its nose,” says a spokesperson for AA.

No personnel were hurt and the plane has been being assessed for damage since the incident on July 15th. AA doesn’t expect any change in schedule due to the absence of this plane.

Terry Maxon with Dallas Morning News’ Airline Biz Blog has several additional photos.

Source: Dallas Morning News