From Heathrow With Love – Photo: Alastair Long | AirlineReporter

Last month, I attended an ultimate behind-the-scenes airport tour, courtesy of London’s Heathrow Airport (LHR). LHR’s Digital Communications Manager, Chris Loy, welcomed a select group of aviation publications to showcase its daily operations and on behalf of AirlineReporter I was thrilled to be a part of it.

Control Tower – Photo: LHR Airports Limited

I always enjoy traveling through LHR, especially Terminal 5 (T5), and revel in what is generally a calm and serene travel experience. This is despite handling more than 75 million passengers and about 1.5 million tons of cargo (the non self-loading variety) per year.

I compare this to the utter chaos that is London’s Luton Airport (LTN) while they undergo extensive construction, or the holiday-maker maelstrom that is Gatwick Airport (LGW) during the summer. That said, I have never transited through LHR. Nor have I ever suffered from any extensive flight delays at the airport.

“Yes, transiting is an operational challenge at Heathrow,” remarks LHR Filming Coordinator and Airside Safety Officer, Joe Audcent. “The airfield is just so big from one end to another.” Chris and Joe would be our intrepid tour guides and I was looking forward to learning more about my hometown airport.

Engine No. 2/vertical stabilizer (“the tail”) of the Orbis MD-10-30F Flying Eye Hospital (N330AU) – Photo: John Nguyen | AirlineReporter

On June 2, Orbis International launched their new, third-generation “Flying Eye Hospital” on board a converted MD-10-30F donated by FedEx. Orbis is a non-profit non-governmental organization (NGO) that aims to provide advanced eye care and medical training to communities throughout the world without access to such facilities, technology, and expertise… literally bringing the hospital to patients and caregivers who need it the most.

I was invited aboard for a special private tour to see this mobile hospital for myself and learn about more its history, design, and purpose, and I created a short video slideshow of highlights…

Not an angle that one sees often of a Boeing 747-400

“We actually don’t do that work here. For that kind of thing, we have to ship it out to Lufthansa Technik in Germany.” If you talk to a great number of airline maintenance employees around the world, you’ll probably hear that line a few times. Many airlines are capable of doing their own aircraft maintenance, but few locations in the world take MRO (Maintenance, Repair, and Overhaul) to the level Lufthansa Technik does.

Airlines around the world send their aircraft to Technik for jobs ranging from a mandatory C check to a nose-to-tail cabin refurbishment. Recently, I was invited to tour Technik’s facilities in Hamburg, Germany, which is just one of their multiple full-service locations around the world.

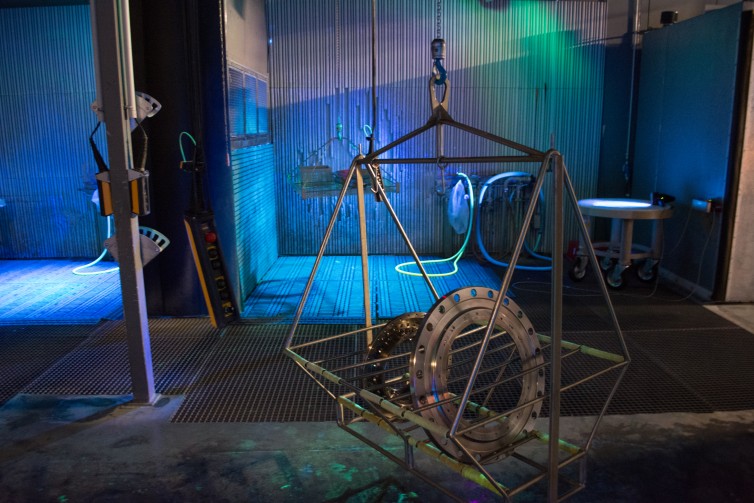

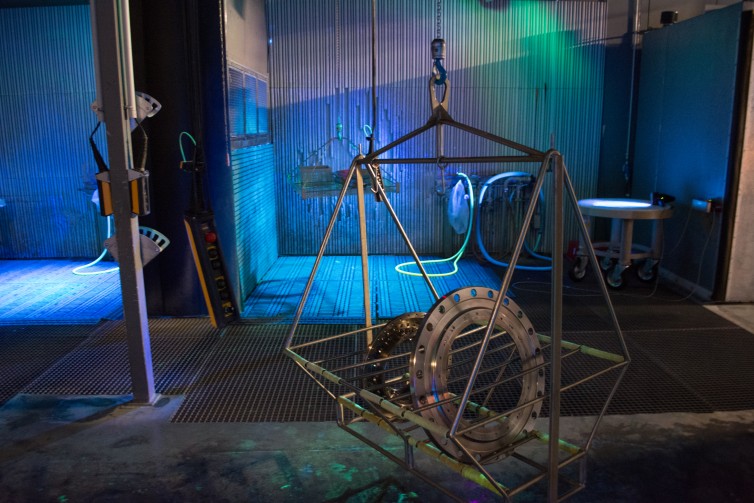

One of the black light inspection areas in Lufthansa Technik Engine Shop – Photo: Jason Rabinowitz

Our first stop on the Engine Services center. Engines are, by far, some of the most expensive parts on any aircraft. Most airlines perform only minor maintenance on their engines, but in the Engine Services center, several engines were completely torn down for a total rebuild.

The Condor 767 crew trainer located in Frankfurt

No matter the size of an airline, they need to provide safety training for their flight attendants. There will be training provided to new hires, as well as reoccurring training for current employees.

It is an important part of making sure an airline operates safely and the more realistic of a training that an airline can provide, the better prepared their flight attendants are going to be to react to an emergency scenario.

Condor’s headquarters is located next to FRA

Recently, I had the chance to get an up-close look at how Condor Airlines manages their flight attendant training at their headquarters in Frankfurt, Germany. I was a bit surprised with some of the things that I learned and how hands-on I was able to get.

Former TAM A320 seen in blue. Two former Avianca birds, an MD-83 and a Fokker F100. Photo by JL Johnson

This is the first in a series of posts I have planned with a focus on the Midwest’s impact on aviation. Dismissed as flyover country by some, much of aviation’s history occurred right here in the middle of the US. It’s not just the past we will be exploring- the Midwest is very much involved in aviation today, and is well positioned to support the evolution of aviation in the future. Join me as we explore the facets of aviation, right here from the heart of America.

What is Jet Midwest? They are a full service MRO (maintenance repair overhaul) firm that is also involved in the purchasing, painting, leasing and recycling of planes.

When Jet Midwest buys planes they are overhauled, leased and/or sold, or parted out. It’s a sad day when a flying machine meets its demise. However, at Jet Midwest, through the sacrifice of one plane, dozens or hundreds more across the globe are able to stay in service. Their motto for what they do: ’œParts to Planes.’

I was recently invited out to tour their huge facility on the southeast corner of the Kansas City International Airport property. The 2.4 million square foot facility, formerly of American Airlines and before that TWA, has hangars that can store multiple 747s, with many more narrow bodies between.